Semiconductor intelligent equipment is building unmanned workshops

With the rise of mechanical automation, the digital production mode has become the trend. At present, automation and flexible production are the goals that manufacturing enterprises are committed to achieving. Introducing mobile intelligent devices is a crucial action for semiconductor industry to advance factory automation and informatization. In the trillion dollar semiconductor industry, intelligent automation equipment is helping to connect production and logistics automation, not only able to adapt to high-frequency production line changes, but also reduce production costs. However, it is worth noting that the working environment of the semiconductor industry also puts forward very strict requirements for automation equipment, such as not affecting the production line rhythm, cleaning operations, shock-absorbing operations, high-precision operations, etc.

In the semiconductor production line, composite robots that can simultaneously achieve both functions of "limbs" have gradually become mature intelligent devices widely used in the semiconductor industry. Similarly, for mobile robot companies, the semiconductor profession is also a highly imaginative Red Sea mall.

In the semiconductor industry, Xiamen Fuqi Automation Equipment Co., Ltd.'s Pre aligner and Load Port are of great help in achieving automated workshops for transportation and handling for enterprises.

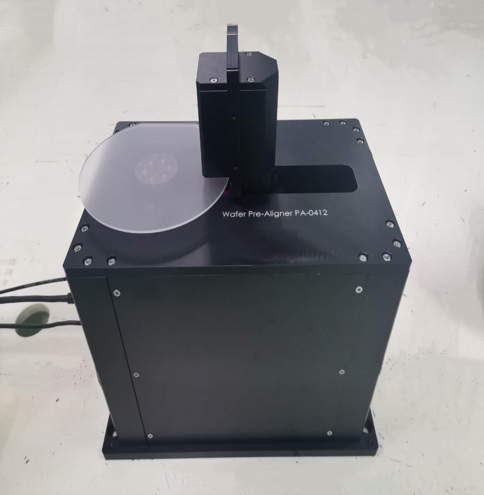

Pre aligner: Chinese name: wafer pre positioning system, wafer calibrator. This device achieves high-precision and efficient pre positioning of the center and flat edges (notches) of 4-12 inch wafer wafers, serving the transportation and handling needs of wafer wafers.

Load Port: Chinese name: wafer loading and unloading machine, wafer loading machine, installed in front of EFEM * (equipment front end module: Equipment Front End Module), used as a window for wafer entry and exit of EFEM. Intelligent and flexible factory interface modules for tool automation; Supporting excellent reliability and ultra clean performance; Maximizing interoperability, seamless interchangeability, and ease of configuration; Compatible with all FOUP and automatic front open shipping boxes (FOSB) delivered manually or through AMHS vehicles that comply with SEMI requirements; Used to maintain the cleanliness of the wafer during transportation.

I believe that in the near future, semiconductor intelligent equipment will create unmanned workshops, which will bring huge dividends to the reduction of labor costs for enterprises.